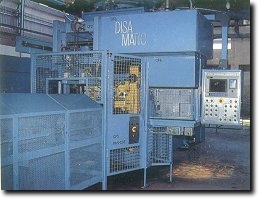

| The

DISA Mould making and Conveyor System is the most advanced facility that

produces dimensionally accurate castings very consistently. The fully

Automatic Sand Plant is controlled by computers which ensure that Sand,

Bentonite, Carbonaceous material and water are mixed in the right proportion.

The DISA Technology facilitates easy storage and retrieval of production

data, easy handling and changing of patterns. Inmould inoculation

and Stream Inoculation are carried out automatically to obtain desired

microstructure and mechanical properties.

Synchronsied

Belt Conveyor System transfers the mould to the DISA Cool Drum where the

castings are seperated from sand. Whereafter the sand is taken back by

conveyor for recycling. The casting then undergo Shot Blasting &

fettling. |